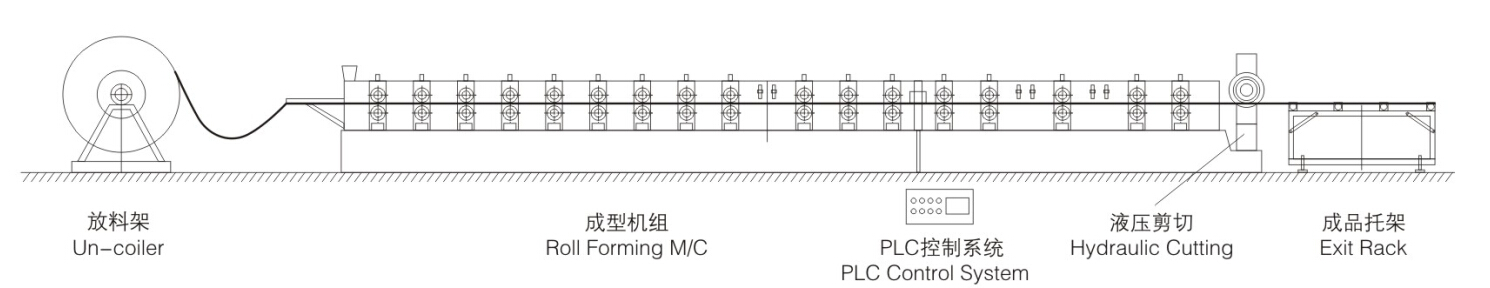

Work process

De-coiling → feeding the material to machine → Roll Forming Machine → hydraulic cutting → Receiving table

Technical parameters

1. Raw material

Material: galvanized steel coil

Thickness: 0.45-0.55mm

Coil width: 325mm

Pipe diameter: 100mm

2. Uncoiler

Type: manual decoiler

Inner diameter: 350-450mm

Outer diameter: 1300mm

Max coil width: 500mm

Capacity:1.5 ton

3. Main forming machine

Forming steps: 25 steps

Shaft diameter: 70 mm

Machine frame: middle plate welded with 16mm thickness

Machine stand: 350# H steel welded with 350mm height

Roller material: 45# steel with quenching, hardening and tempering

Shaft material: 45# steel

Main power: 5.5 kw

Transmission: By chains

4. Cutting system

Cutting type: hydraulic cutting

Mold material: CR12Mov

Oil pump: 3 kw

5. Control system

Control system: PLC control system

PLC brand: Delta from taiwan

Function: auto control cutting length and quantity, oil pump on and off